Drill tools

1. Soil layer double bottom bucket :

It is suitable for silt, fine sand, silt, silty clay, clay, and some soft soil types, such as completely, strongly weathered and weathered mudstone, muddy sandstone, etc. It is the most widely used drill tools in the industry.

2. Rock-embedded double bottom bucket :

Suitable for egg and gravel layers, weathered soil-like soft rocks, such as weathered argillaceous sandstone, argillaceous conglomerate, and harder rocks with higher degree of weathering, such as fully and strongly weathered granite. When drilling hard rock, it is often necessary to use core barrel and rock auger .

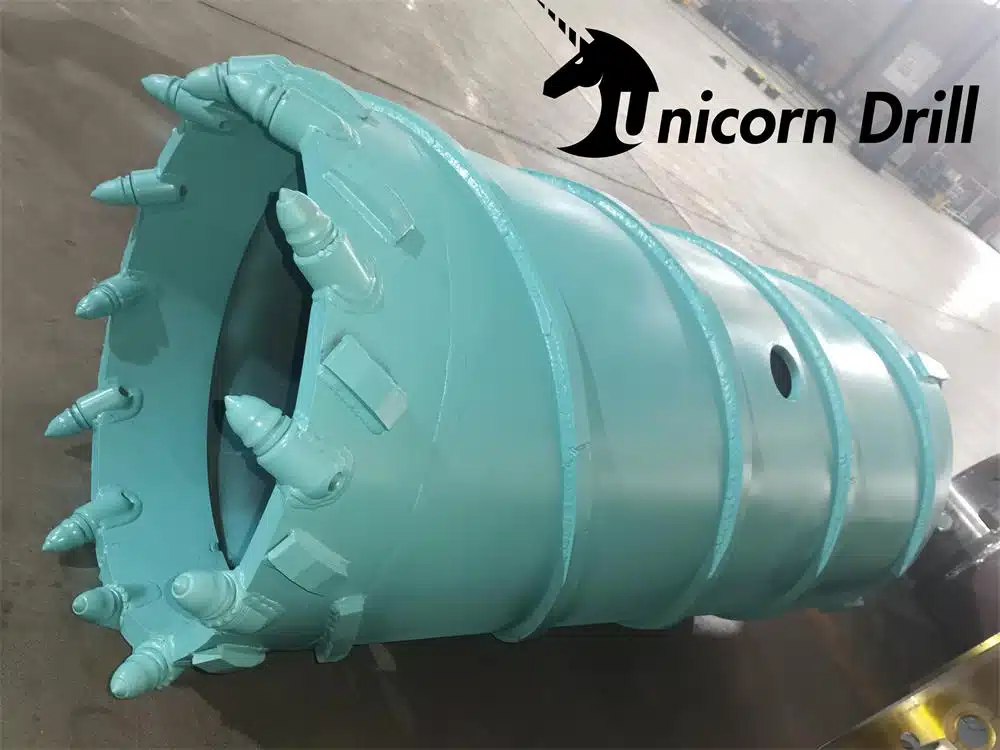

3. Core Barrel :

It is suitable for circumferential cutting of moderately weathered sandstone with obvious layering (high probability of coring) and hard rock formations. In soil layers with high density or some soft rock formations, when friction-type drill pipes are selected to cause slippage, you can try to use barrel drills.

4. Centrifugal bucket :

The Centrifugal bucket is used to realize automatic opening. The cylinder and the bottom plate are connected as one. When drilling, the two-flap cylinder is closed. After lifting the drill, the two-flap cylinder is opened and the clay drilling residue falls naturally, reducing the time and time of soil throwing. It has the advantages of fast drilling speed and convenient soil dumping.

In the early days of its produce, the centrifugal bucket bucket was mainly used in clay layers that were difficult to dump. Now its scope of application has expanded to sedimentary rocks and fully weathered rocks with lower strength.

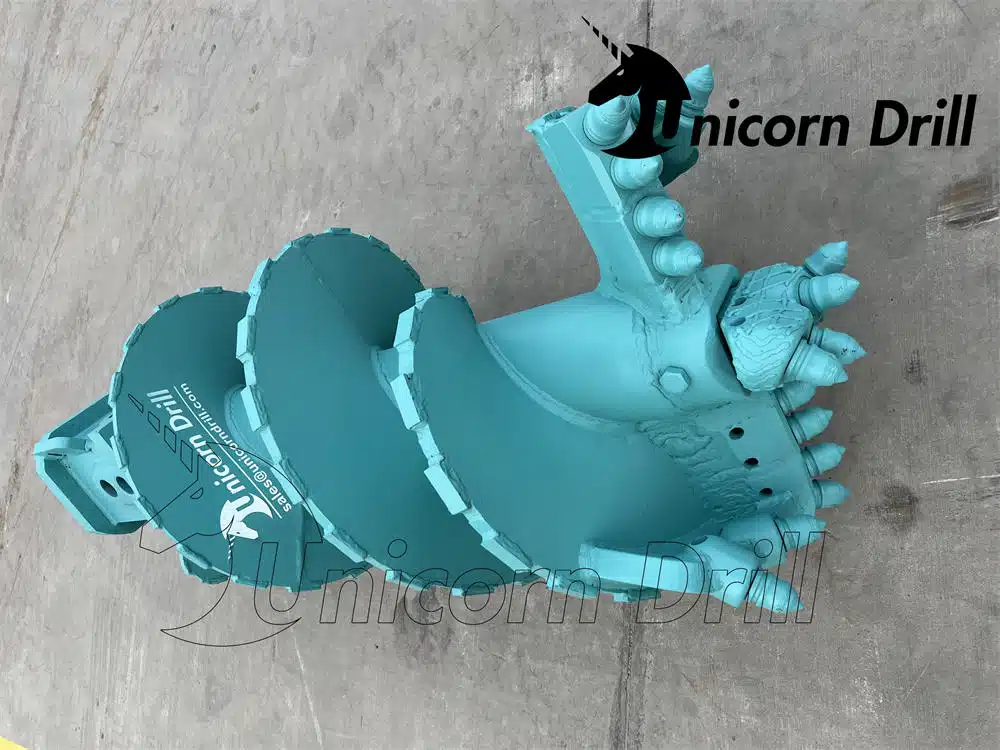

5. Rock-embedded drill auger:

It is suitable for crushing hard rock formations such as boulders and boulders in the hole. For some cement formations and medium-density pebble soil, when the double-bottomed bucket cannot be used to drill, you can try to use a auger t to drill

6. Double-layer core barrel:

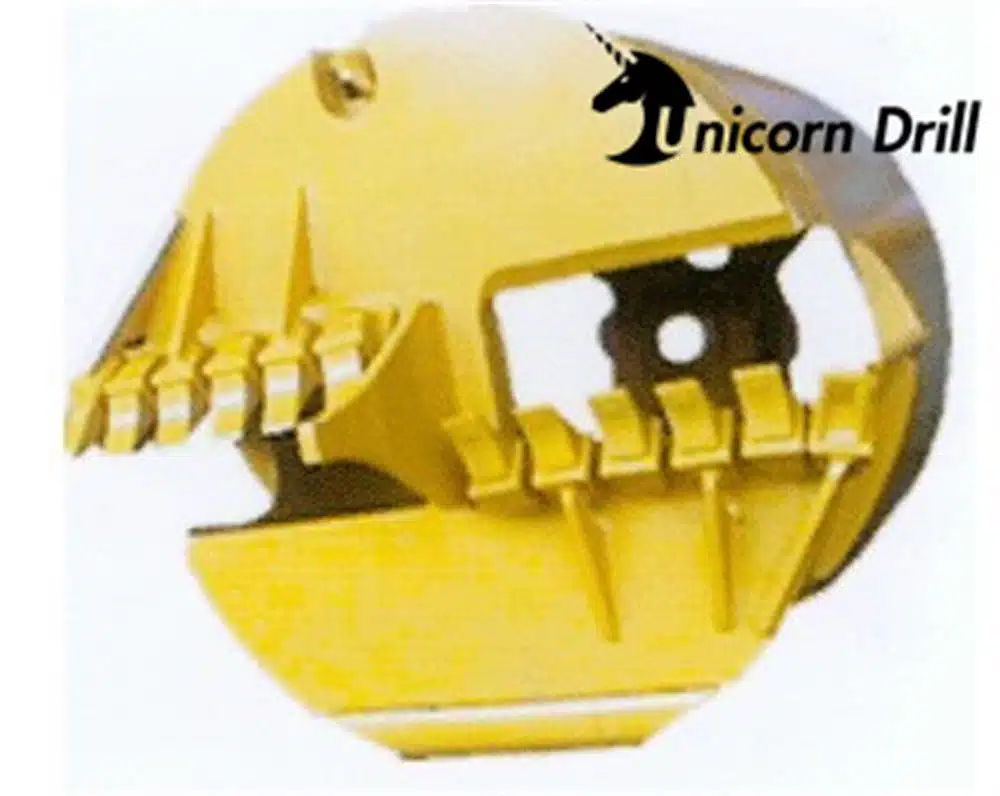

7. soil layer single bottom bucket:

This drill bit has similar functions to the double-bottom bucket. The advantage is that it has a side soil inlet and does not need to be reversed to close the bucket door, so it is more efficient in drilling soil layers. Due to its light weight, the single bottom bucket may slip and fail to penetrate some hard soil layers, especially when used with friction kelly bar, that will affect the drilling efficiency.

8. Soil auger:

9. Double bottom single cut bucket:

10. Bottom expansion drill tools:

On the basis that the pile diameter does not increase and the pile depth does not increase, in order to improve the bearing capacity of a single pile, the design unit often achieves it by expanding the base of the pile. The base expansion of the rotary drilling rig can be constructed without any modification. Just choose the base expansion. Just drill.

The most commonly used base expansion drill tools are mechanical ones. This type of drill tools is relatively simple to use and maintain. There are top-opening and bottom-opening types. The opening mechanism is usually a four-link. It is used in soil layers, strongly weathered, and moderated strata. . Since rotary drilling is non-circulatory drilling, just use a slag cleaning bucket to clean the slag after the bottom expansion is completed