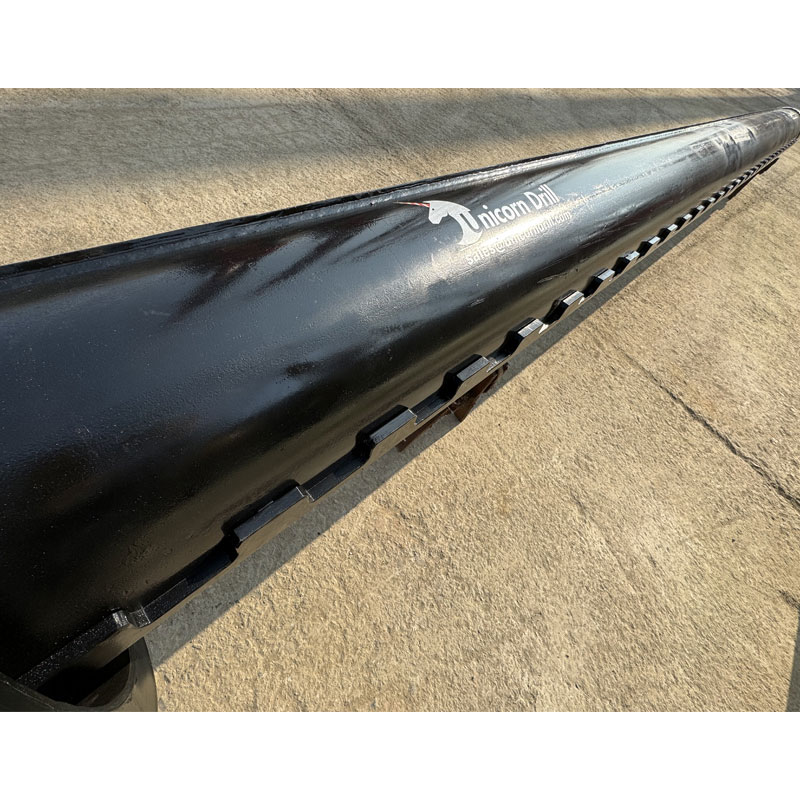

Our Kelly Bars are premium rotary rig tools designed for deep foundation drilling in large-scale construction and infrastructure projects. Compatible with various rotary drilling rigs,Like IMT,MAIT,Bauer and Etc… they provide maximum efficiency and durability in challenging soil and rock conditions.

Parameters

*Other size could be customized

(Kelly box option :130*130/150*150/200*200/ETC)

Spring :customized base on the rigs

(Kelly box option :130*130/150*150/200*200/ETC)

Spring :customized base on the rigs

Features

- High Torque Transmission: Ensures effective torque transfer for powerful drilling.

- Multi-Stage Telescopic Design: Adaptable to different drilling depths, with Full locking kelly bar

- Heavy-Duty Alloy Steel(XT52/Q355B and 35CrMo): Built from high-strength steel for exceptional durability.

- Protective Wear Coating: Resists wear and extends tool life in abrasive environments.

Advantages

- Versatility: Works with multiple rig types and adapts to different soil and rock conditions.

- Efficiency: Quick extension and retraction reduce cycle times, boosting productivity.

- Durability: Built to withstand high-torque demands with minimal maintenance.

- Customizable: Dimensions and torque specifications can be tailored to project needs.

Our Services

- 24/7 Online Support

- Available round-the-clock via email, chat, or phone for questions, technical support, and troubleshooting.

- After-Sales Service

- Warranty: Covers parts and labor for one year or 2000 working hours for added assurance.

- Technical Support: Rapid assistance with operational issues

- Replacement Parts: Quick access to necessary parts to keep you on schedule

- Maintenance Tips: Expert guidance to ensure peak performance

- Visual Production Tracking

- Real-time updates with photos and videos to track your order from start to finish.

Delivery & Packaging

(Wooden box packaging & Film covering packaging)

Reviews

There are no reviews yet.